6463 alloy and bright dip anodizing, the best partner for shiny aluminum tile trim production

6463 alloy and bright dip anodizing

Bright dip anodizing and 6463 alloy

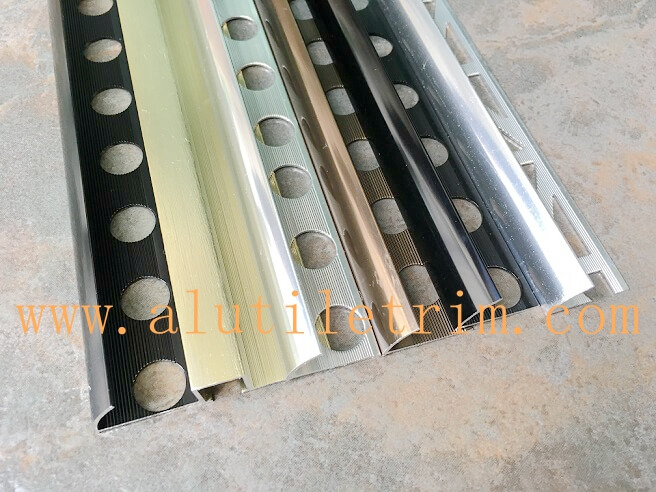

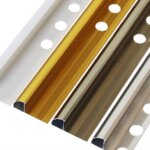

In aluminum tile trim market, it is easy to get shiny aluminum tile trim products, like shiny silver, shiny gold, shiny bronze and other shiny colors.

The production process is aluminum extrusion, polishing and bright dip anodizing.

If you want to get reliable and stable quality shiny aluminum tile trim products, bright dip anodizing and 6463 Alloy are best partner in the production process for high quality shiny aluminum tile trim products.

Bright dip anodizing

Bright Dip anodizing enhances the glossy appearance of aluminum for cosmetic applications and achieves a highly reflective surface finish similar to mechanical polishing.

In contrast to plating, Bright Dip is a chemical process that brightens aluminum and does not leave deposits on the surface of the part.

The degree of brightness is dependent on the type of alloy as well as the surface finish of the part.

The bright dip aluminum procedure is often used as a pretreatment for anodizing to enhance the aesthetic qualities of a part.

Referred to bright dip anodizing, the bright dipped aluminum goes through the anodizing process to prevent corrosion, scratching or fading on the alloy.

The anodizing steps are where you can have your aluminum alloy dyed in different colors.

Products made from selected alloys and properly prepared by buffing and polishing are used to produce automotive, appliance, and aluminum tile trim.

Many items, such as truck and automotive mirrors are often mistaken as being chrome plated.

Bright decorative colors are widely used in the manufacture of sports equipment such as mini-mag flashlights, paintball guns, tennis rackets and baseball bats.

Process Description

The process is a phosphoric/nitric acid based chemical polishing pre-treatment.

A very rigid relationship of several factors must be maintained at all times.

Concentration of nitric acid, phosphoric acid, aluminum in suspension, specific gravity, and temperature must be constantly in balance.

Since the process is performed at a relatively high temperature, it requires a very strict control of chemicals together with technical skill and experience.

One of the best alloys for bright dipping is 6463 aluminum. In fact, it was specifically developed for this purpose.

It’s a variant of 6063 and has similar properties. That means it’s good for architectural trim and is suitable for both bright dipping and anodizing.

6463 alloy

6463 aluminium alloy is an alloy in the wrought aluminium-magnesium-silicon family (6000 or 6xxx series).

It is related to 6063 aluminium alloy (Aluminum Association designations that only differ in the second digit are variations on the same alloy), but unlike 6063 it is generally not formed using any processes other than extrusion.

It cannot be work hardened,but is commonly heat treated to produce tempers with a higher strength but lower ductility. Like 6063, it is often used in architectural applications.

Alternate designations include AlMg0.7Si(B) and A96463. The alloy and its various tempers are covered by the following standards:

- ASTM B 221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- EN 573-3: Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- EN 755-2: Aluminium and aluminium alloys. Extruded rod/bar, tube and profiles. Mechanical properties

Chemical composition

The alloy composition of 6463 aluminium is

- Aluminium: 97.9 to 99.4%

- Copper: 0.2% max

- Iron: 0.15% max

- Magnesium: 0.45 to 0.9%

- Manganese: 0.05% max

- Silicon: 0.2 to 0.6%

- Zinc: 0.05% max

- Residuals: 0.15% max

Properties

Typical material properties for 6463 aluminum alloy include

- Density: 2.69 g/cm3, or 168 lb/ft3.

- Young’s modulus: 70 GPa, or 10 Msi.

- Ultimate tensile strength: 130 to 230 MPa, or 19 to 33 ksi.

- Yield strength: 68 to 190 MPa, or 9.9 to 28 ksi.

- Thermal expansion: 22.1 μm/m-K.

A few reasons to use bright dipping

- Used to remove heavy scales and oxides from metal surfaces

- Can impart a wide range of appearances from matte, bright, and lustrous depending on the metal and electroplating process

- In certain circumstances, it can be used to remove metal to get parts into tolerance.

- Can help remove burrs and other surface defects in the base metal

Bright dipping anodizing and 6463 alloy, the best partner in the production for shiny aluminum tile trim products.

Honstar Aluminum Products use 6463 alloy for aluminum tile trim production, we offer high glossiness and stable quality aluminum tile trim products for our customers.

Contact us now to check the difference between 6063 and 6463 alloy products, make your products different in your market if you buy 6463 high glossiness and shiny aluminum tile trim products from us.

Get Free Samples And Mold List Here