The general 3 mechanical finishes for aluminum tile trim before anodizing

The general 3 mechanical finishes for aluminum tile trim before anodizing

Aluminum tile trim 3 kinds of mechanical finishes before anodizing

Mechanical finish methods can give aluminum tile trim several different types of surface texture – from rough or patterned to a mirror finish.

Here are the most 3 mechanical finishes for aluminum tile trim before anodizing

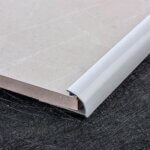

1.Brushing:

A brushed finish is cosmetically appealing and looks like stainless steel.

Brushing is beneficial for blending extruded die lines and covering some imperfections.

It is available in a wide range of textures based on different brushing mesh wheels.

Aluminum tile trim profile can be anodized in different colors or bright dipping anodizing after the brushing.

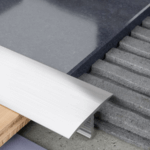

2.Polishing:

Polishing gives aluminum profiles a smooth and shiny surface.

After going through aluminum profile polishing machine, they come out with a significant specular reflection and mirror-like look.

A soft cloth charged with abrasive grains is run over the extrusions to create this effect.

This process was called mechanical polishing.

For high quality aluminum tile trim, this is the most important before chemical polishing.

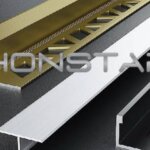

3. Shot blasting/sand blasting:

Blasting produces a unique granular appearance that can hide a lot of imperfections with a wide range of textures.

This type of mechanical finish is an outside operation with associated lead-time costs.

Some of these costs can be offset as bead blasting can cover up defects thus resulting in higher yields for each applied part.

Besides the above 3 major mechanical finishes, there are grinding, buffing and hammer pinned mechanical finishes for aluminum tile trim, all belong to mechanical finishes and that will make aluminum tile trim products more pattern and texture.

Aluminum tile trim products need to be anodizing or bright dipping anodizing after mechanical finishes.

Honstar offer mechanical finishes and chemical finishes for aluminum tile trim products.

Tile trim extrusion, mechanical finishes and chemical finishes under one roof allows for minimized lead times, reduced production costs, and improved end product quality to our valued customers.

It avoids finger pointing between subcontractors and the extruder if defects occur, reducing potential customer headaches.

Contact us now for your aluminum tile trim product supply chain. Honstar offers total solution and one stop shop service.

Get Free Samples And Mold List Here