Extrusion process, aluminum tile trim production third step

Extrusion process, aluminum tile trim production third step

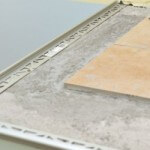

Aluminum tile trim production extrusion process

Aluminium extrusion, is one process by which aluminum is forced into a custom-made die and results in a constant cross-section that utilizes all the properties of the metal.

As tile trim molds were designed and aluminum billets are available in the first step and second steps.

All is ready for tile trim extrusion.

Tile trim aluminum profiles will be carried out on an automatic production line consisting of billets heating, extrusion, cooling, tension straightening, sawing and other processes.

Equipment on the production line, including multi billets heating furnace, extrusion press, run-out table, stacker, profile conveyor, cooling bed, tension straightening machine, storage platform, puller, profile sawing machine, etc.

The billet heating temperature is generally controlled at 400 ° C ~ 520 ° C, too high or too low a temperature will directly affect the aluminum tile trim shape.

The working temperature of the extrusion tool is 360 ° C ~ 460 ° C, and the extrusion speed is 20 m / min ~ 80 m / min.

After aluminum tile trim extrusion is done, will be sawed in the extrusion line.

As it is soft and we need to make them aging for the hardness in the aging furnace.

Now aluminum tile trim profile will be got and it is only mill finished tile trim.

It is only the start, we need to make them punched, mechanical process and chemical process to get different finishes to match the project.

We will see what happens in the next process.

Get Free Samples And Mold List Here